Strength

We have our own research center. The center has a noise free chamber which can also be used as a semi-anechoic chamber, two reverberation chambers. The three Laboratories can be used independently. And they also can be used as a soundproof room.

We have our own research center. The center has a noise free chamber which can also be used as a semi-anechoic chamber, two reverberation chambers. The three Laboratories can be used independently. And they also can be used as a soundproof room.

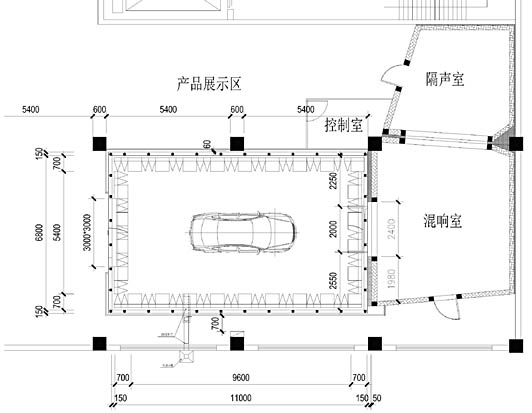

Size:

Semi-anechoic chamber:Length*width*height=9.6×5.4×4.2(h)m

Full anechoic chamber:Length*width*height=9.6×5.4×3.4(h)m

Background noise:

15dB(A), the requirement of environmental noise is less than 60dB,with no source of vibration and noise sources, close the air conditioning and ventilation system.

Cut-off frequency: 100Hz

Free Field Radius:far-field:3.9m,near-field:1.8m。

Free field accuracy (ISO 3745-2012, Single frequency signal test) :

Full anechoic chamber

When used as a full anechoic chamber with laying the modular grid under which placed acoustic wedges, the lab can meet the performance of the full anechoic chamber.;

The function of the full anechoic room can meet the needs of accurate measurement and calibration of acoustic instruments, musical instruments, sound level meters, microphones, reference sound sources and other acoustic devices. Acoustic performance analysis of electroacoustic products such as acoustic products, speakers and buzzer, speakers, earphones, stereos, speakers, TV sets, home theatres, etc.. Able to meet the requirements of noise testing for IT products (printers, computers, scanners, etc.)

The design meets the following standards:

GB 6882-1986   Acoustics, Determination of sound power levels of noise sources; Precision methods for anechoic and semi-anechoic rooms

ISO 3745–2003 Acoustics-Determination of Sound Power Levels of Noise Sources Using Sound Pressure-Precision Methods for Anechoic and Hemi-anechoic Rooms

GB 50800-2012 Technical code for anechoic and semi-anechoic rooms

JJF 1147-2006 "Calibration Specification for Acoustic Performance of Anechoic Rooms and Hemi-anechoic Rooms"

CNAS-CL15Guidance on the application of Laboratory Competence Accreditation Criteria in the Field of Electro-acoustic Testing.

SJ/T10660-95 General specification for sounders and buzzers

SJ/T10382-93 Methods of measurement for sounders and Beeps

GB/T 14198-2012 General specification for microphones

GB/T12060.4-2012 Methods of measurement for microphones

GB/T12060.5-2011 Methods of measurement for main characteristics of loudspeakers

Semi-anechoic chamber

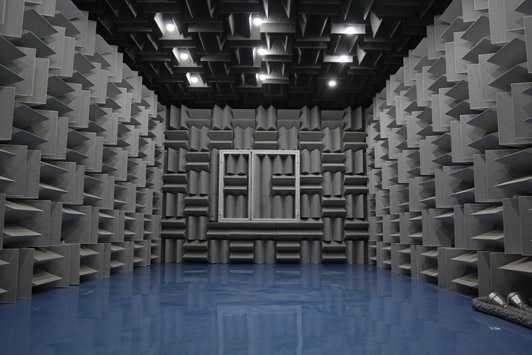

When used as a Semi-anechoic chamber, the modular grid and acoustic wedges are moved outside the room. The floor surface is an epoxy floor, which ensures the use characteristics of the semi-anechoic chamber.

The function of semi-anechoic chamber: to meet the requirement of noise testing of the vehicle stationary, vehicle interior, auto Parts, and the measurement of noise limits of refrigerator, washing machine, small appliances, computers, etc.

The design meets the following standards:

GB 6882-1986 Acoustics, Determination of sound power levels of noise sources; Precision methods for anechoic and semi-anechoic rooms

ISO 3745–2003 Acoustics-Determination of Sound Power Levels of Noise Sources Using Sound Pressure-Precision Methods for Anechoic and Hemi-anechoic Rooms

GB 50800-2012 Technical code for anechoic and semi-anechoic rooms

JJF 1147-2006 "Calibration Specification for Acoustic Performance of Anechoic Rooms and Hemi-anechoic Rooms"

CNAS-CL15 Guidance on the application of Laboratory Competence Accreditation Criteria in the Field of Electro-acoustic Testing.

GB/T4214.1 Acoustics-Household and similar electrical appliances-Test code for determination of airborne acoustical noise Part 1: General requirements and GB/T4214

GB/T 18313 Acoustics-Measurement of Airborne Noise Emitted by Information Technology and Telecommunications Equipment

ECE R51 Uniform provisions concerning the approval of motor vehicles having at least four wheels with regard to their noise emissions.

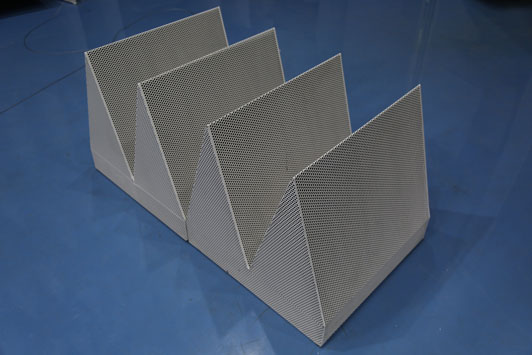

Acoustic wedge

The specification of the metal acoustic wedge is 600*600*600mm with the installation cavity is 100mm. The total length is 700mm. Acoustic wedges were arranged around the walls and roof with the combination of sound absorbing materials which have different density. The surface of wedges is metal perforated boards.

Grounding Grid

For the convenience of interchange between full and semi-anechoic chamber, the grid is modular frame structure with the total height is 740mm. The grid framework is made of steel wire with the wedges installed under it.

Soundproof door

The Soundproof door is a door installed wedges and has the function of sound insulation and sound absorption. It can be opened and closed freely. The wedges on the door can be inosculated with those on the wall when the door is closed.

The gate size is 3.0*3.0 (H) M.

Acoustic window

The acoustic window is the test window used between the anechoic chamber and the reverberation chamber. Its size is 2.0*1.8 (H) m. It can be opened and closed freely. The wedges on the window can be inosculated with those on the wall when the window is closed.

Exhaust extraction system

The system applies the high temperature fan with low noise which can remove the exhaust gas effectively when the vehicle is running. It can be disassembled and equipped with a hose that is resistant to 400 DEG C.

Lighting electrical appliance

The lighting uses mute energy saving lights which guarantees the work area illumination 300lux. There are two sets of socket in the chamber. All the pipelines passing in and out the anechoic chamber have been acoustic processed.

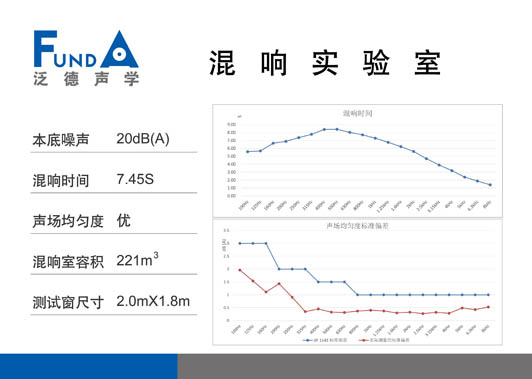

Volume of Reverberation rooms:221m³ and 102.5m³

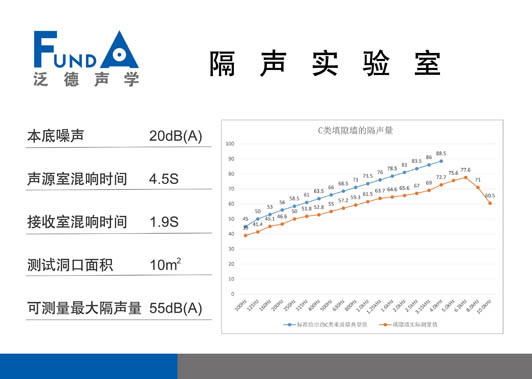

Background noise:20dB(A)

Diffusion characteristics of sound field in reverberation rooms:

Requirements of the acoustic field distribution uniformity in GB/T 6881.1

Octave Band f, Hz | 1/3 Octave Band f, Hz | The maximum of standard deviation, dB |

100 ~ 125 | 80 ~ 160 | 1.5 |

250 ~ 500 | 200 ~ 630 | 1.0 |

1000 ~ 2000 | 800 ~ 2500 | 0.5 |

4000 ~ 8000 | 3150 ~ 10000 | 1.0 |

The maximum sound transmission loss can be measured with the soundproof room (two reverberation rooms): 50dB.

The soundproof room is consists of two reverberation rooms and one anechoic chamber which can interchange between full and semi anechoic chamber.

When the reverberation chamber is used alone, it can meet the requirement of measurement for acoustic absorptivity of the building materials and components, the sound power of the electromechanical products, etc. The design meets the following standards:

GB/T 20247-2006 / ISO354:2003 Acoustics - Measurement of sound absorption in a reverberation room;

ISO 354:2003 Acoustics -- Measurement of sound absorption in a reverberation room;

JJF 1143-2006 Calibration Specification for Acoustic Performance of Reverberation Rooms

GBT 6881.1-2002 Acoustics--Determination of sound power levels of noise sources using sound pressure--Precision methods for reverberation rooms

When the two reverberation chambers are used as a soundproof room, the soundproof room can meet the requirement of sound transmission loss measurement of building materials, doors, windows, etc. The design meets the following standards:

GB/T 19889.1~18-2005 Acoustics—Measurement of sound insulation in buildings and of building elements—Part 1-18

ISO 140:1991 Acoustics -- Measurement of sound insulation in buildings and of building elements -- Part 1-18

ISO 10140-1:2010 Acoustics -- Laboratory measurement of sound insulation of building elements -- Part 1: Application rules for specific products

ISO 10140-2:2010 Acoustics -- Laboratory measurement of sound insulation of building elements -- Part 2: Measurement of airborne sound insulation

ISO 10140-3:2010 Acoustics -- Laboratory measurement of sound insulation of building elements -- Part 3: Measurement of impact sound insulation

ISO 10140-4:2010 Acoustics -- Laboratory measurement of sound insulation of building elements -- Part 4: Measurement procedures and requirements

ISO 10140-5:2010 Acoustics -- Laboratory measurement of sound insulation of building elements -- Part 5: Requirements for test facilities and equipment

When the reverberation chamber and the anechoic chamber are used as a soundproof room, the soundproof room can meet the requirement of the noise measurements of the whole vehicle and parts of the North America (ECE). The design meets the following standards:

ECE R51 Uniform provisions concerning the approval of motor vehicles having at least four wheels with regard to their noise emissions.

Sound insulation treatment

根据现场环境状况,为保证达到需要的本底噪声和良好的声场环境,从节省成本的角度出发,建议做240mm实心砖墙体,双面抹灰后粉刷。利用原有的屋面做顶面。

The whole room is plastered and polished and painted, and the sound insulation cotton is filled in between the two walls.

Characteristics of sound field

The reverberation room is designed to increase the reverberation time of the room so as to ensure the dispersion of the interior sound field. The maximum reverberation time is determined by the molecular absorption of air at high frequencies, and depends on the absorption of walls, ceilings, and floor surfaces at low frequencies. Materials used commonly are tiles or terrazzo.

The shape of a reverberation chamber is an irregular room or a rectangular room with the length is the harmonic series. The walls and top surfaces are polished with mortar and painted, and then glazed tiles are laid on the ground, and the reflecting plate is suspended according to the sound field.

When used as a soundproof room, the reverberation time of the room should be controlled. So the diffuser and absorber must be made to be conveniently disassembled. Thus, when the sound insulation quantity testing is carried out, the absorber can be used conveniently and can be quickly installed. When the reverberation chamber is testing, the absorber needs to be conveniently and rapidly disassembled.

Ground Treatment

The ground in the room is covered with fully reflesting glaszed tiles with the thickness is 50mm and the sound absorption coefficient is less than 0.01. There is 10 m^2 gray sound absorption test indication area on the ground.

Soundproof door

The size of the door is 1.2 * 2.1m with the thickness is 100mm. It can be opened and closed lightly and can stay at any angle. There is the design of sound absorption structure between the two doors, to form the structure of sound lock to avoid the acoustic resonance in the cavity.

It's a fireproof soundproof door which is made of sound insulation steel plate, sound proof cotton, etc. It is processed with professional acoustic design and strict manufacturing process. Design of double tongue-and-groove, using high quality hinges, door lock and sealing strip to ensure well sealed, opened lightly and comfortably and can stay at any angle. Surface treatment: electrostatic powder coating. The door has good appearance.

Test window

A test window with an area of 10 square meters is arranged between the two reverberation chambers, and the civil structure is acoustically treated so as to facilitate installation and removal of the test piece in the future.

A test window with the size is 2.4*2.0m is arranged between the reverberation chamber and the anechoic chamber, with the acoustic processing. It can be opened and closed freely. The wedges on the window can be inosculated with those on the wall when the window is closed.

Lighting electrical appliance

LED mute energy-saving lamps are distributed on the top of the reverberation chamber to ensure that the indoor illumination is not less than 500Lux.

1 concealed electric box are installed in the room. 4 electric outlets which is AC220V are installed. A 75mm threading pipe is reserved, and all the pipelines passing in and out the anechoic chamber have been acoustic processed.